?

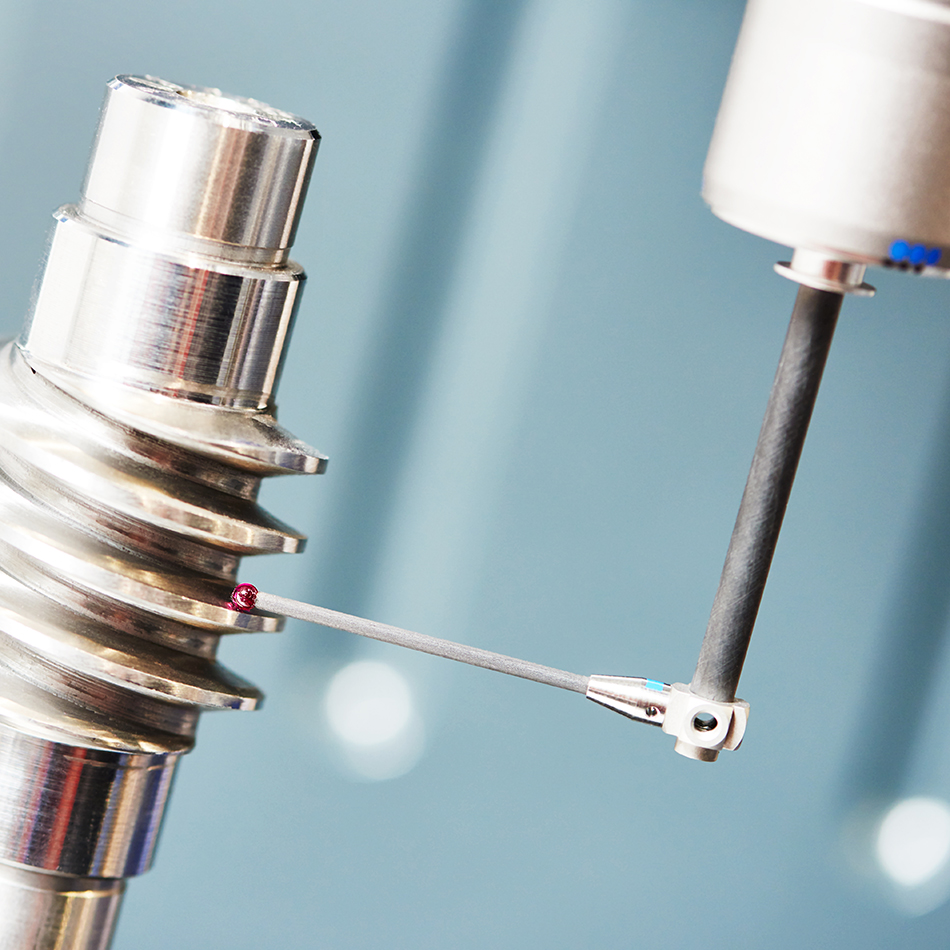

Materials: Bearing steel and stainless steel are recommended.

Precision grade: C3/C5 (repeatable position accuracy is up to 8μm.)

Diameter: >16mm

Thread direction: Left-hand/Right-hand

Circulation method:? Internal circulation

?

How to determine the preload of a ball screw?

Applying preload to the nut in a ball screw assembly can enhance the axial stiffness and positioning accuracy of the ball screw pair. Therefore, if only considering the stiffness and positioning accuracy of the ball screw pair, a larger preload is more beneficial, as it can better eliminate axial clearance caused by elastic deformation. Conversely, an excessively small preload, even if it eliminates axial clearance, does not necessarily improve stiffness.

?

This is because the preload must be sufficient to eliminate the "low-stiffness zone" in the preloaded nut. Due to inherent errors (such as lead errors) between the ball screw shaft and nut components in the preloaded section of a double-nut assembly, some segments may exhibit higher contact stiffness after deformation (due to tighter contact), while others may show lower stiffness (due to looser contact). The latter is what is referred to as the "low-stiffness zone." To improve axial contact stiffness, the preload must be large enough to eliminate such low-stiffness zones, thereby truly achieving enhanced axial stiffness.

?

However, an excessively large preload is also detrimental. It will increase the driving torque, reduce transmission efficiency, accelerate contact fatigue and wear between balls and raceways, and shorten the service life.

Causes of Backlash in Ball Screws

?

Excessively tight or loose preload of the ball screw

1. Large manufacturing errors of the ball screw or axial movement

2. Excessively tight or loose pressure plate in the fit between the screw shaft and slide plate

3. Interference from other mechanical components

4. Loose taper sleeve of the screw shaft coupling

5. Excessively tight or loose preload of the ball screw support bearing

6. Excessively tight or loose wedge in the fit between the ball screw shaft and slide plate