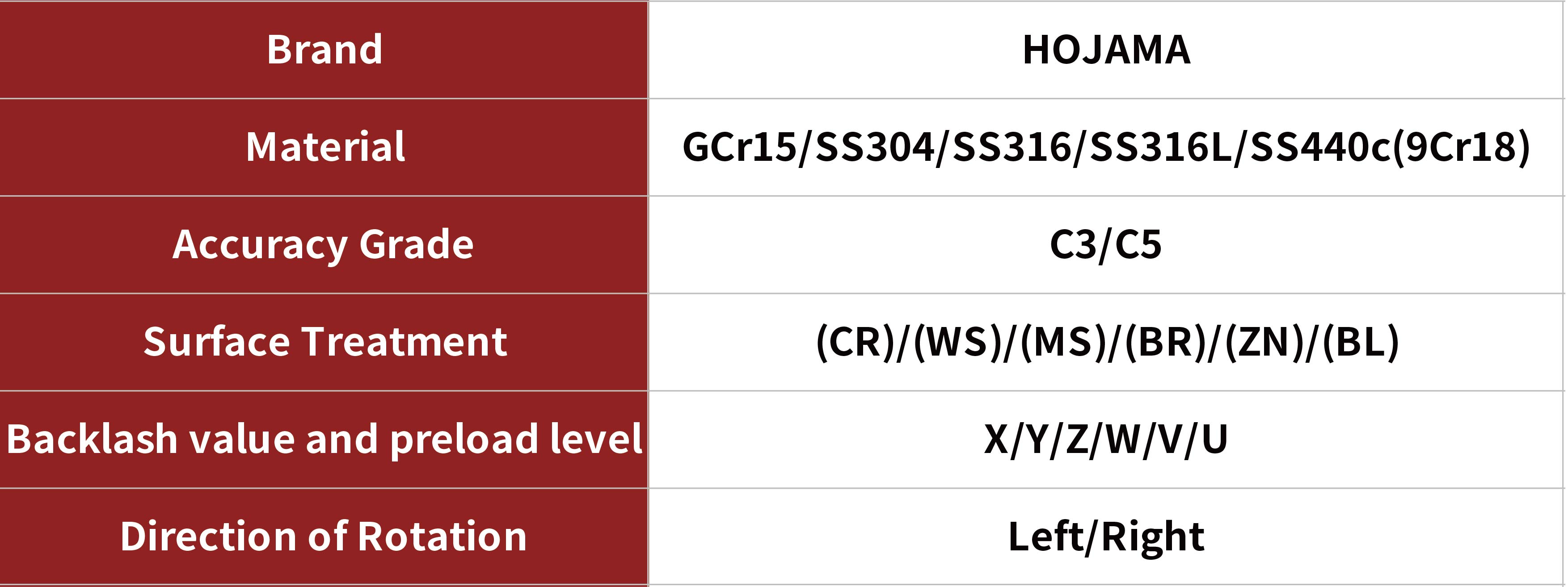

1. Key Parameters?

Accuracy Grade: C5

2. Performance Highlights?

1) Precision?

We can provide three accuracy grade options for ball screw, including C3/C5/C7.

2) Durability?

Constructed from high-quality stainless and bearing steel, this ball screw offers high rigidity and excellent resistance to wear and corrosion.

3. Applications?

1) CNC Machine Tools?

In CNC machining centers, lathes, and milling machines, the mini ball screw plays a crucial role in driving the linear motion of worktables, spindles, and other components. Its high precision ensures that complex parts with tight tolerances can be machined accurately. Whether it's creating intricate molds or manufacturing high-precision mechanical parts, this ball screw enables consistent and reliable machining results, meeting the strict quality standards of the manufacturing industry.?

2) Precision Measuring Instruments?

Coordinate measuring machines (CMMs) and other precision measuring instruments rely on the accurate linear movement provided by this ball screw. The C5 accuracy grade is essential for obtaining reliable measurement results. When measuring the dimensions and shapes of workpieces, the screw's precise motion allows the measuring probe to reach the correct positions accurately, ensuring the accuracy and repeatability of the measurements. This is vital in quality control processes across various industries, from automotive to aerospace.?

3) Automation Equipment?

In pick-and-place robots, automated assembly lines, and other automation systems, the ball screw controls the movement of robotic arms and actuators. Its low-friction and high-speed capabilities enable fast and efficient operation, enhancing the productivity of the automation process. For example, in an automated electronics assembly line, the screw allows the robotic arms to quickly and accurately pick up components and place them on circuit boards, increasing the production speed while maintaining high assembly quality.?

4) Medical Equipment?

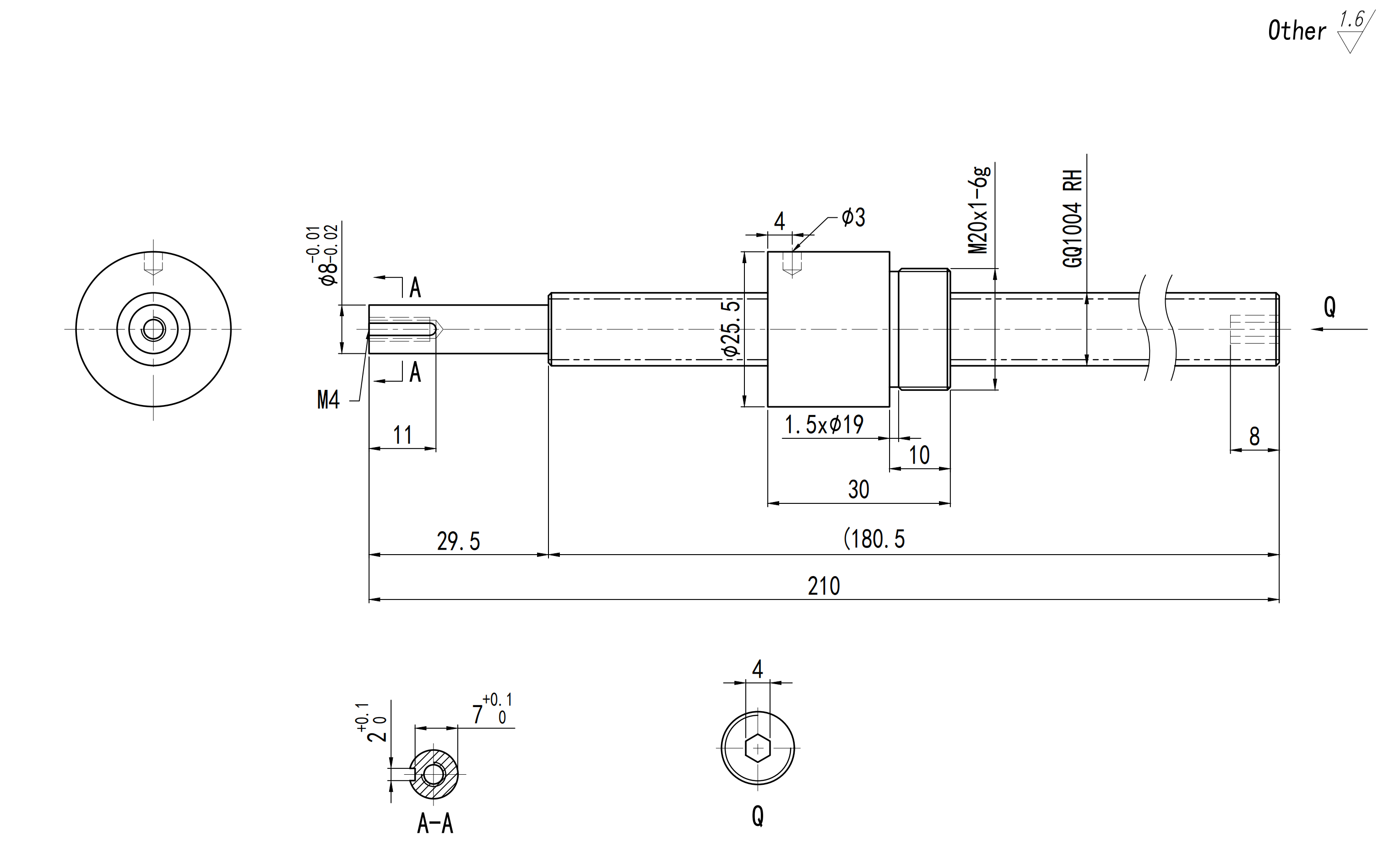

In medical devices such as surgical robots, X-ray machines, and precision diagnostic equipment, the GIA1205-180.5-210-C5 ball screw provides the precise linear motion required for the accurate positioning of components. In surgical robots, the screw's high precision is crucial for performing minimally invasive surgeries with extreme accuracy, reducing patient trauma and improving surgical outcomes. In diagnostic equipment, it ensures the correct positioning of imaging components, enabling clear and accurate medical images for reliable diagnosis.