Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

$29.99-299.99 /Piece/Pieces

| Sample: |

$300.00 /Piece/Pieces, 10 Piece/Pieces (Max. Order)

|

?

Preloading refers to applying an axial force to the balls, screw shaft, and nut grooves of the Ball Screw kit, ensuring their tight fit. This process can enhance rigidity and eliminate backlash. Backlash is the loss of motion caused by the gap between the balls and the nut or screw raceways, which is crucial for applications requiring precise positioning.

?

Common preloading components in ball screw assemblies include:

(1) Shim preloading: Shim preloading is achieved by placing shims between two ball nuts. The shims exert force on the adjacent sides of the two nuts, which is then transmitted to the nuts and grooves. This method is typically used to set larger preloading forces.

?

(2) Spring preloading: Springs are placed between two ball nuts to transmit the preloading force, and the springs apply tension to the adjacent sides of the ball nuts.

?

(3) Offset lead preloading: During processing, the grooves are offset on the lead line at the center of the circulation loop. This method is more compact than the double-nut mechanism as it eliminates the need for shims or springs, but it will increase the lead length and reduce the load-carrying capacity.

?

(4) Oversized ball preloading: Oversized ball preloading involves using larger ball bearings to generate preloading force, increasing the contact area between the balls and the grooves, resulting in a more compact structure. However, this method generates the smallest preloading force and is suitable for applications with low precision requirements.

?

Lubrication is crucial for ball screw assemblies, as it helps prevent premature wear and improves performance by reducing friction and heat. Both oil and grease have cooling effects. Overheating can cause thermal expansion of components, thereby affecting the accuracy of the ball screw system.

?

Poor lubrication can lead to wear, which is the microscopic tearing of metal surfaces due to continuous friction. This problem is common in nuts, bolts, threaded fasteners, and ball screw threads, and is detrimental to the function of ball screw pairs.

?

Installation refers to the support method of the ball screw and ball nut during operation. To make full use of the lead accuracy of the ball screw set, precise installation is essential! Improper installation may cause noise, vibration, positioning errors, and may even lead to material failure and accelerated wear. We should regularly inspect and repair faults in auxiliary components such as bearings, couplings, and nut brackets to maintain installation accuracy.

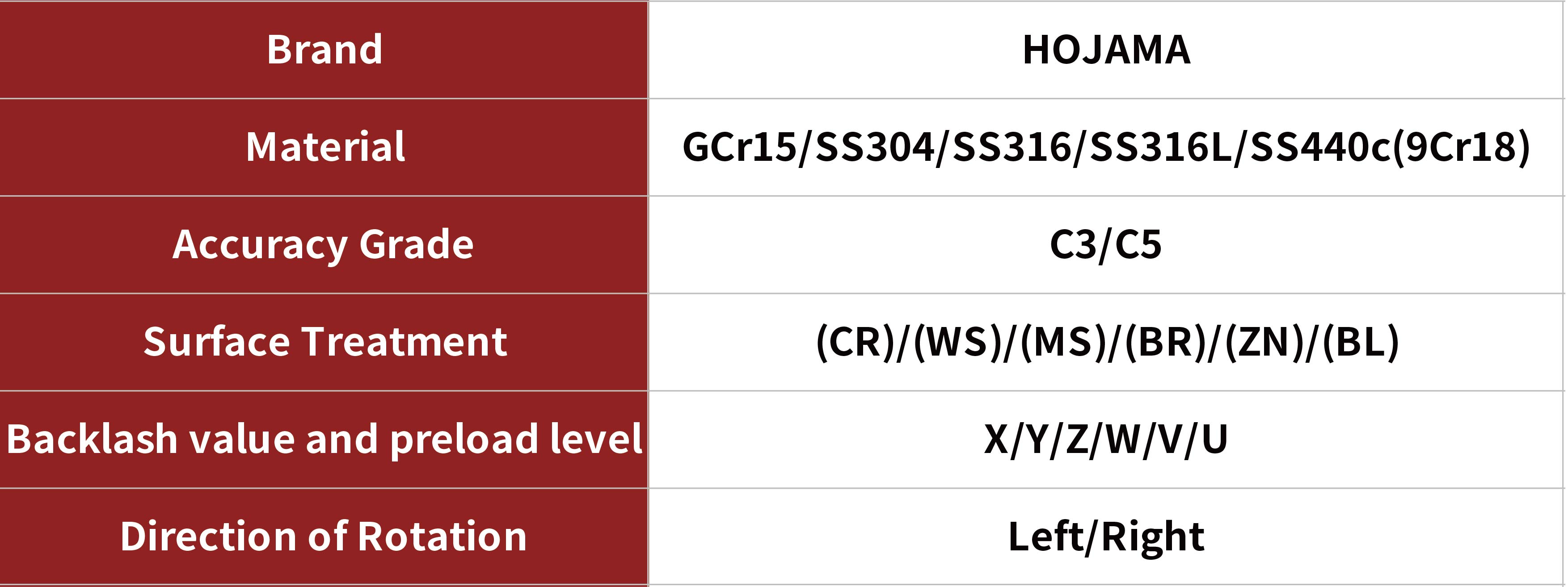

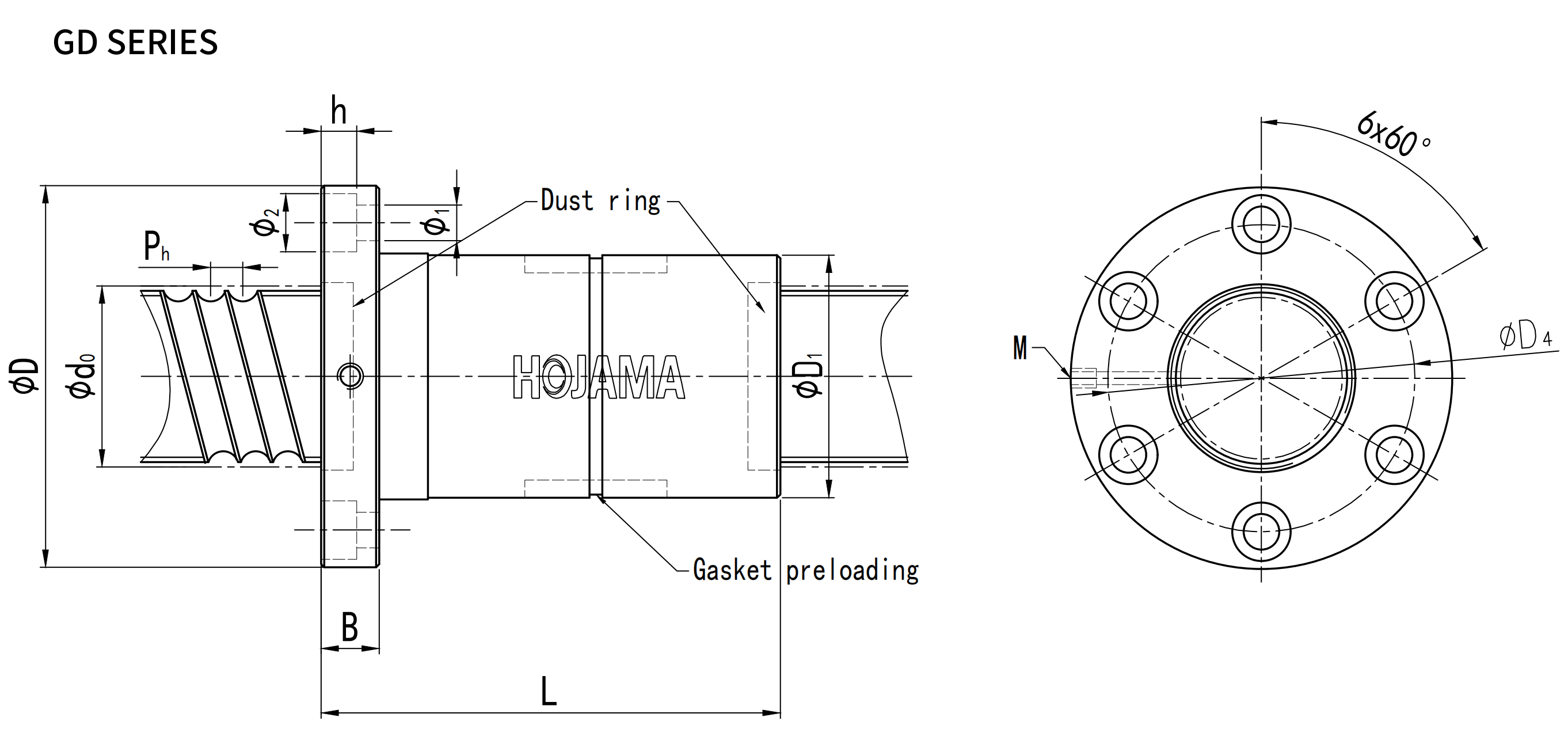

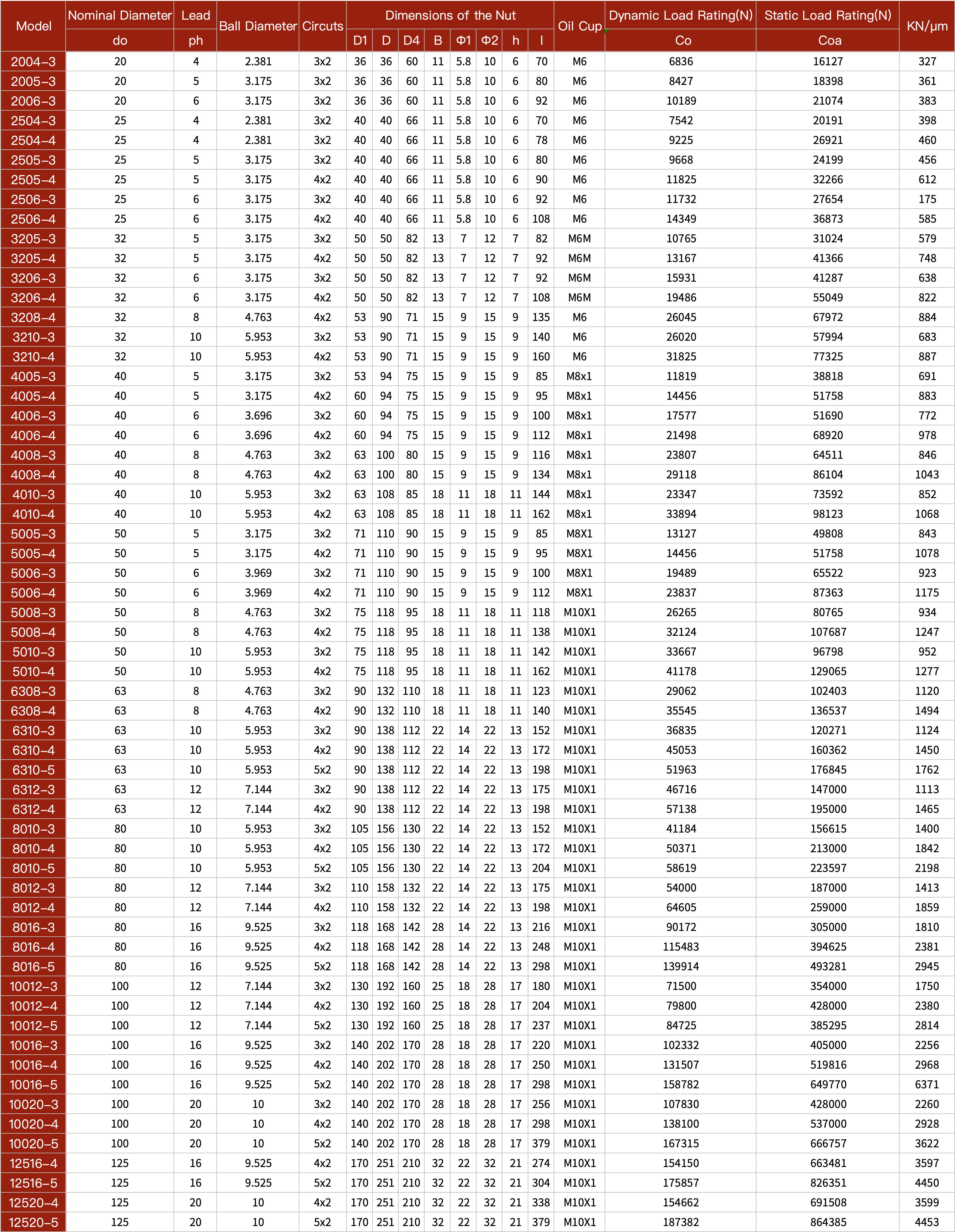

At Hojama, we can offer you all kinds of linear motion products, including ball screws, Lead Screws, linear guides, Linear Modules and Ball Splines. Welcome to make an order.

?

?

The file is encrypted. Please fill in the following information to continue accessing it

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.