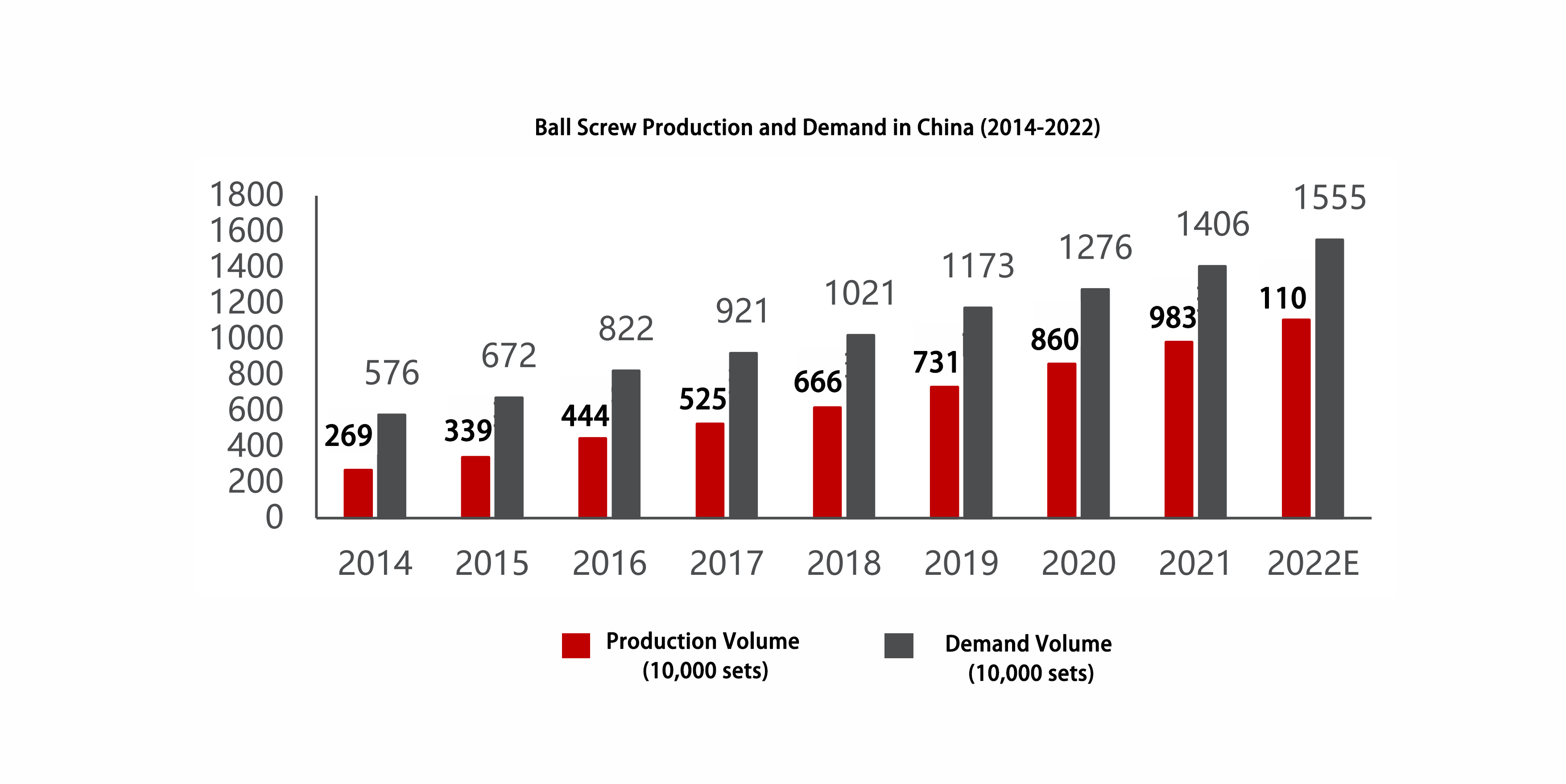

I. Continuous Growth of Market Demand

1. Steady Growth in Traditional Industries

High-Precision Ball Screws are essential components for ensuring precise motion control. As the traditional manufacturing industry increasingly demands higher production accuracy and efficiency, the need for linear motion ball screws will continue to grow.? ?

2.Emerging Industries Bring More Opportunities

Emerging industries such as new energy vehicles, robotics, and semiconductor manufacturing are developing

rapidly, leading to a growing demand for Ball Screw products.? ?

?

II. Technological Innovations Drive Industry Upgrades

1. Continuous Performance Improvement

To enhance the lifespan and reliability of ball screw assmeblies, new high-performance materials (such as ceramics and special alloys) are being applied in production. These materials improve the product’s wear resistance, corrosion resistance, and high-temperature tolerance. Additionally, continuous upgrades in manufacturing processes are also vital to the industry’s advancement. For example, CNC processing and precision manufacturing technologies can improve product accuracy and surface quality.?

?

2. Intelligent Developmen

With the maturity of the Internet of Things and artificial intelligence (AI) technologies, the intelligence of ball screws is accelerating. By integrating sensors for temperature, vibration, displacement, and other factors, high-performance ball screws can monitor their operational status in real-time. Data can be transmitted to central control systems for analysis, enabling fault warnings or automatic adjustments.

?

III. Policy Support Accelerates Industry Development

1. Government Support

Many governments are actively implementing policies to support high-end equipment manufacturing and intelligent manufacturing, providing a favorable policy environment for the ball screw industry.

?

2.Accelerating Domestic Substitution

Encouraged by national policies, Chinese ball screw companies are increasing their investment in research and development to improve technology levels and product quality. More and more domestic companies are now capable of competing with international rivals, thus accelerating the process of domestic substitution.

?

IV. Growing Emphasis on Sustainable Development

1. Environmentally Friendly?

Environmental concerns are increasingly becoming a global focus, and ball screw companies are intensifying their efforts in green manufacturing. More environmentally friendly materials and processes are being used in ball screw production, balancing production efficiency and environmental protection, and enhancing the sustainability of products.

?

2. Recycling of Waste Resources

With the growing awareness of environmental protection, used ball screws will gradually be recycled and converted into other usable materials or products.

?

3. Extending Product Lifespan

By optimizing designs and utilizing intelligent control technologies, the reliability and lifespan of our high-quality ball screws will be effectively extended, reducing the frequency of product replacements. This, in turn, reduces resource consumption and waste generation, aligning with the requirements of sustainable development.

?

V. Challenges and Intense Competition

1. Supply Chain Issues

Globalization has led to supply chain instability, particularly for companies that rely on imported materials or raw materials. Fluctuations in the supply chain may impact production.

?

2.Intensifying Technological Competition

The competition in the ball screw industry is becoming increasingly fierce. To stand out among numerous competitors, companies must continuously innovate technologically and differentiate their products. Only through technological breakthroughs can they maintain a competitive edge in the market.