Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

?

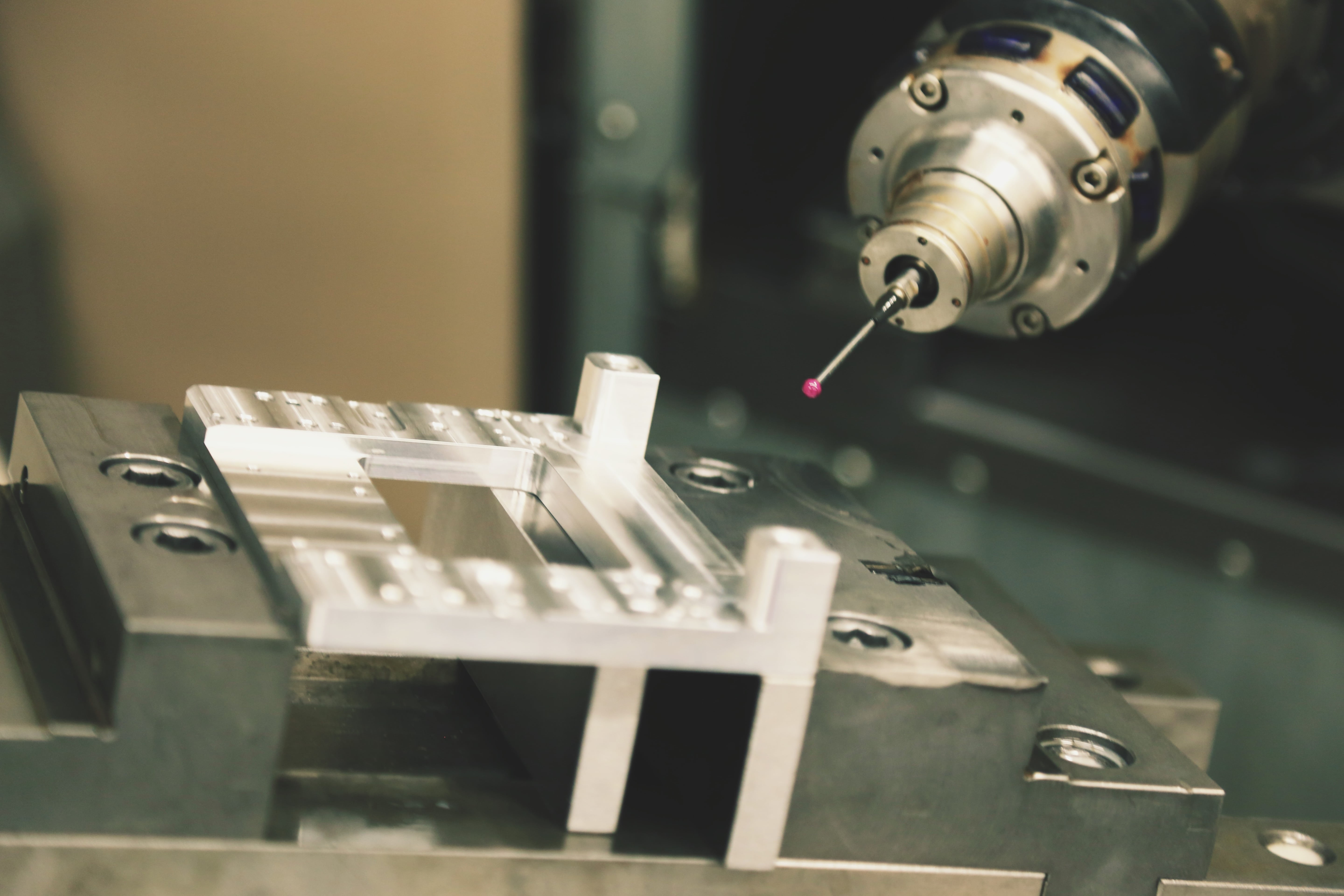

Collect the vibration signals of the linear motion ball screw pair through acceleration sensors or displacement sensors.

?

Utilize signal processing techniques such as filtering and envelope to extract information such as fault characteristic frequencies and amplitudes.

?

Based on the characteristics of the vibration signal, determine whether there is a fault in the ball screw and ball nut assembly and its type.

?

?

Use noise sensors to collect noise signals when the ball screw pair is in operation.

?

Perform spectral analysis and sound pressure level analysis on the collected noise signals to extract the features of the noise.

?

Determine the fault types of the ballscrew pair, such as ball wear and screw bending, according to the noise characteristics

?

Install temperature sensors at the critical parts of the ball screw assemblies to monitor temperature changes.

?

Process and analyze the temperature data, and extract temperature characteristics such as temperature changing trends and temperature rising rate.

?

3)?Fault Diagnosis

?

Determine whether there is a fault in the ball screw kit, such as poor lubrication and overload, according to the temperature characteristics.

?

1) Lubricating oil collection

Regularly collect lubricating oil samples of the ball screw pair.

?

2) Analysis of the Oil Sample

Conduct physical and chemical property analysis, metal element analysis, contamination degree analysis, etc. on lubricating oil.

?

3) Fault Diagnosis

Based on the analysis results of the lubricating oil, determine the wear condition, lubrication state, and fault type of the ball screw pair. For example, if the content of metal elements in the oil exceeds the standard, it may indicate that the balls or the screw are worn.

June 25, 2025

June 24, 2025

Ball screws are essential components in medical devices, providing the precision and reliability necessary for various applications in healthcare technology. They convert rotational motion into lin

一、Tesla has achieved multiple innovative breakthroughs in the application technology of lead screws in the fields of automobiles and humanoid robots. In the automotive field, the application of ball...

The differences in the application of screw products between domestic new energy vehicles and Tesla vehicles: 一、Application 1. Domestic new energy vehicles: 1) Battery production and assembly: The...

Failure Prevention and Maintenance of Ball Screw Sets 1. Regular inspection and maintenance 1) Check the wear condition of the ball screw pair The entire wear inspection encompasses the balls, screw...

Email to this supplier

June 25, 2025

June 24, 2025

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.