Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Regular maintenance of the Lead Screw is beneficial to prolong its service life and enhance its function. The following are some maintenance matters regarding Hojama Lead Screws:

?

?

Hojama recommends that the frequency of lubrication and maintenance for lead screws can be set to 1 time/three months. Regular maintenance helps keep the leadscrew running smoothly and avoid potential hazards caused by friction and wear. However, for lead screws used in high-usage or dusty and other harsh environments, the frequency of lubrication and maintenance should be appropriately increased.

?

?

?

?

?

?

?

?

?

1) Cleaning cloth (tissue, old rag, etc.)

?

2) Lubricant (grease or lubricant)

?

3) Brush

?

4) Disposable gloves

?

?

?

1) Reserve enough space for applying the lubricant.

?

2) Place a tissue or cleaning cloth under the working area to remove excess lubricant and particles generated during the first cleaning of the screw.

?

3) Wear gloves for proper personal protection.

?

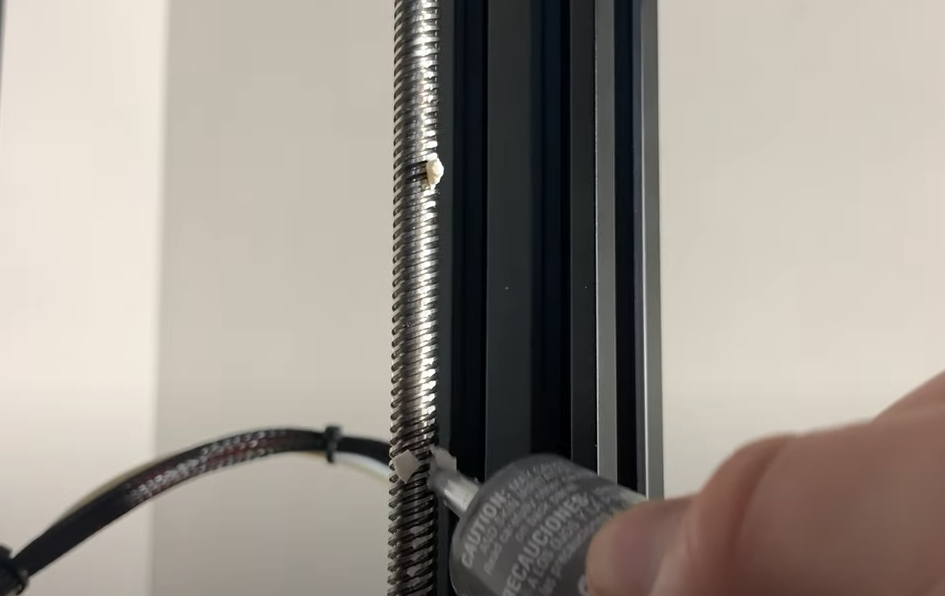

4) Use the cloth to remove dust and plastic particles from the lead screw.

?

5) Apply a thin layer of lubricant on the lead screw.

?

6) Remove the excess lubricant near the lead screw nut.

?

7) After completing the lubrication of the lead screw product, ensure that no substance drips from the screw.

?

8) Take out the tissue/cloth to absorb the excess part.

?

9) Run the equipment using the lead screw several times to check for improvement.

?

10) Record the lubrication time to track the lubrication frequency and the need for lead screw repair.

?

Before delivering lead screw products to customers, Hojama will implement a strict quality inspection process and add lubricating oil or grease at the same time. In this way, the best performance of the product is guaranteed, so that customers can smoothly put the lead screw into use after receiving it, and it runs normally and efficiently, achieving maximum customer satisfaction.

June 25, 2025

June 24, 2025

一、Tesla has achieved multiple innovative breakthroughs in the application technology of lead screws in the fields of automobiles and humanoid robots. In the automotive field, the application of ball...

The differences in the application of screw products between domestic new energy vehicles and Tesla vehicles: 一、Application 1. Domestic new energy vehicles: 1) Battery production and assembly: The...

Fault Diagnosis Methods and Technologies 1. Vibration Analysis Method 1) Vibration signal acquisition Collect the vibration signals of the linear motion ball screw pair through acceleration sensors...

Email to this supplier

June 25, 2025

June 24, 2025

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.