Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

A ball screw spline is a combination of two components: a ball screw and a rotating ball spline. By integrating the driving element (the ball screw) with the guiding element (the rotating ball spline), the ball screw spline, which is high in rigidity and compact in design, can provide linear and rotational motion, as well as helical movement.

?

?

?

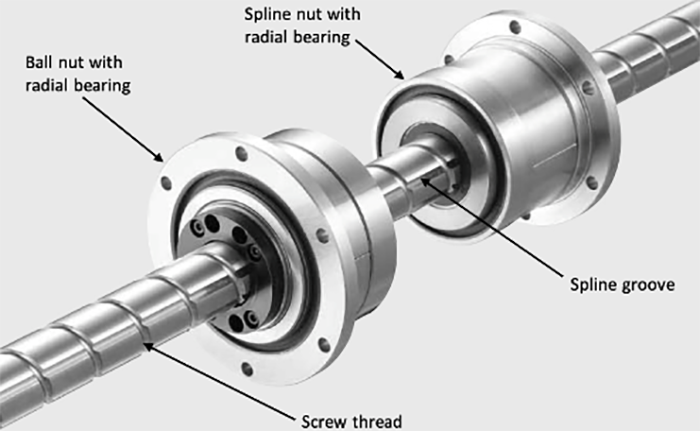

Another design of the ball screw incorporates radial angular contact bearings on the outer diameter of the nut, allowing the nut to be driven—typically through a belt and pulley assembly connected to a motor—while the screw remains completely stationary. When the motor rotates, it turns the nut, enabling it to traverse the length of the screw. This setup is commonly referred to as a "driven nut" design.

?

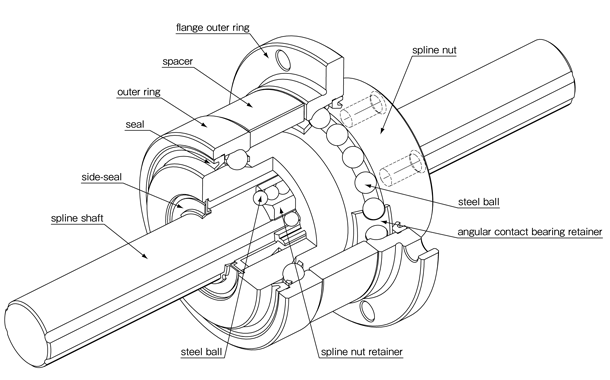

A ball spline is a Linear Guide system similar to a round shaft and circulating ball bearing, but it features precisely machined spline grooves along the length of the shaft. These grooves prevent the bearings (referred to as the spline nut) from rotating while allowing the ball spline to transmit torque.

A variant of the standard ball spline is the rotating ball spline, which incorporates a rotating element, such as a gear, crossed roller, or angular contact ball bearing, on the outer diameter of the spline nut. This design enables the rotating ball spline to provide both linear and rotational motion.

?

?

?

?

When a driven nut-type ball screw assembly is combined with a rotating ball spline, the resulting configuration is commonly referred to as a ball screw spline. The shaft of the ball screw spline features both threads and spline grooves along its length, with the threads and grooves intersecting.

This design allows for the efficient transmission of both linear and rotational motion, as the driven nut moves along the threaded section while simultaneously engaging with the spline grooves, providing high precision and effective torque handling capabilities.

A ball screw spline consists of a ball nut and a spline nut, each equipped with a radial bearing on its outer diameter.

?

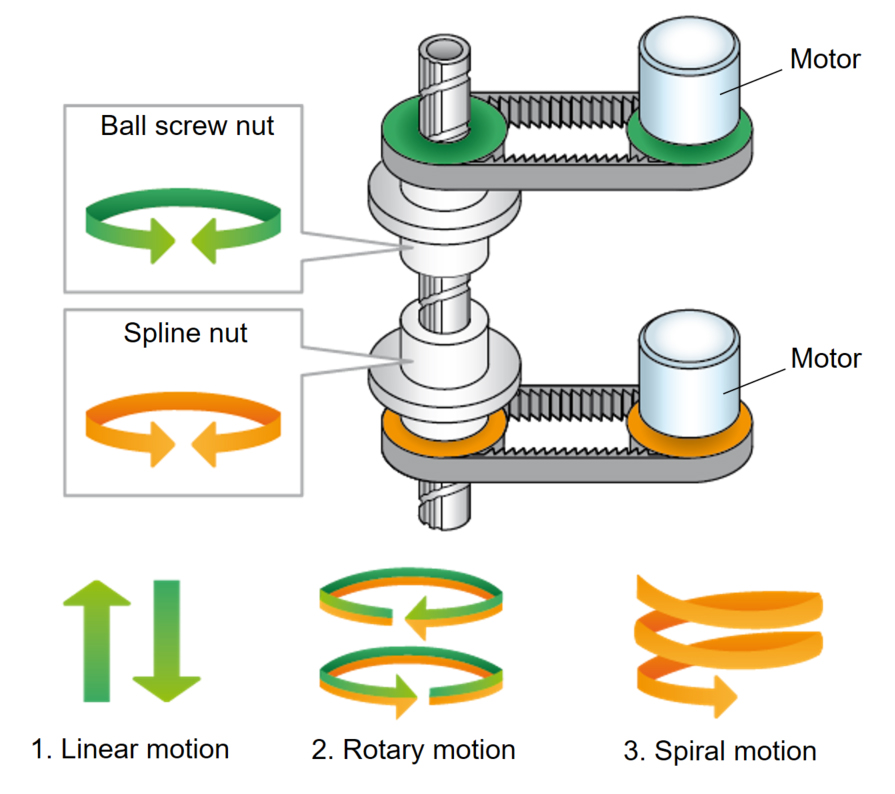

The ball screw spline assembly restricts the linear movement of both the ball nut and the spline nut. By driving the ball nut and spline nut together or separately, three distinct types of motion can be generated: linear motion, helical motion, and rotational motion.

To produce linear motion, the ball nut is driven while the spline nut remains stationary. The ball nut cannot move linearly, so the shaft passes through it. However, the fixed spline nut prevents the shaft from rotating, resulting in purely linear motion without any rotation.

Alternatively, when the spline nut is driven while the ball nut remains stationary, the ball spline induces rotational motion, and the threads passing through the fixed ball nut allow the shaft to move linearly as it rotates, creating helical motion.

When both nuts are driven, the rotation of the ball nut essentially cancels out the linear motion induced by the ball spline, causing the shaft to rotate without any linear travel.

In a ball screw spline assembly, the ball screw nut and spline nut can be driven individually or together to produce linear, helical, or rotational motion.

?

June 25, 2025

June 24, 2025

Ball screws are essential components in medical devices, providing the precision and reliability necessary for various applications in healthcare technology. They convert rotational motion into lin

一、Tesla has achieved multiple innovative breakthroughs in the application technology of lead screws in the fields of automobiles and humanoid robots. In the automotive field, the application of ball...

The differences in the application of screw products between domestic new energy vehicles and Tesla vehicles: 一、Application 1. Domestic new energy vehicles: 1) Battery production and assembly: The...

Fault Diagnosis Methods and Technologies 1. Vibration Analysis Method 1) Vibration signal acquisition Collect the vibration signals of the linear motion ball screw pair through acceleration sensors...

Email to this supplier

June 25, 2025

June 24, 2025

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.